Cold precision forging

Unlike the casting method where metal heated to melting is poured into the casting mold, or the cutting method where materials are cut and shaped, the "cold precision forging method" uses the principle of "plastic deformation" to cause deformation of metal when a force above a certain level is applied.

Unlike the casting method where metal heated to melting is poured into the casting mold, or the cutting method where materials are cut and shaped, the "cold precision forging method" uses the principle of "plastic deformation" to cause deformation of metal when a force above a certain level is applied.

Compared with the cutting method and other processing methods, where the fiber flow (fibrous tissue) lined up in parallel under strictly correct conditions is cut off, it is vastly superior in terms of strength or precision, enabling high-speed processing and avoiding generation of cutting debris, to enable major reduction in manufacturing costs.

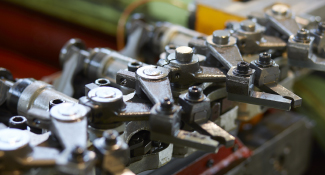

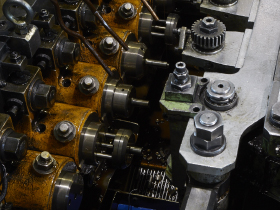

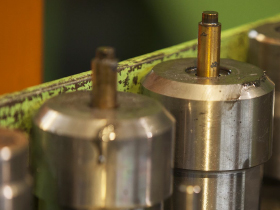

Metal molds

At the company, metal molds are manufactured with 100% in-house designs.

At the company, metal molds are manufactured with 100% in-house designs.

With pursuit of near net shaping, if the amount of change in one round of formation is large, the wear on the metal mold becomes severe, and a stable product cannot be finished. This level is difficult to predict even with a forging simulation. However, after a certain degree of simulations, we at the company view with seriousness tries on real machines, and are shortening this cycle of Try on real machine → Verification and metal mold correction → Retry to as short as one day and a half, to achieve early stabilization.