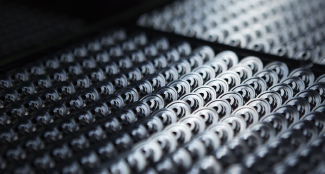

Precision cutting

Cutting process refers to use of a blade tool for removal of metals and various other materials, for precision processing of shapes required for products.

Cutting process refers to use of a blade tool for removal of metals and various other materials, for precision processing of shapes required for products.

At the company, our most common cutting process method is the lathe cutting process. We engage in daily research and development, and use the latest facilities to achieve automated processing precision of 1/1000 to 1/100 mm. We can also use cutting to respond to products that in the past were processed by grinding, which leads to major shortening of processing time.

NC lathe

With consideration for the texture, shape, or hardness of the material to be cut, based on long years of experience, we achieve processing in the shortest possible cutting cycle time, satisfying the completeness precision. In regards to materials that are difficult to process using cutting tools available on the market, we utilize detailed analysis of current conditions, and abundant know-how, for joint development with the various manufacturers of the optimum cutting oil, etc., for the tool type, blade shape, material to be cut, and cutting conditions.

With consideration for the texture, shape, or hardness of the material to be cut, based on long years of experience, we achieve processing in the shortest possible cutting cycle time, satisfying the completeness precision. In regards to materials that are difficult to process using cutting tools available on the market, we utilize detailed analysis of current conditions, and abundant know-how, for joint development with the various manufacturers of the optimum cutting oil, etc., for the tool type, blade shape, material to be cut, and cutting conditions.

In addition, we actively propose cutting allowance reduction to engineering departments or forging work sites, aiming with daily improvements toward materials yields of 90% or more and a 1 chuck cutting cycle time of 25 seconds or less at the longest.