Technology development

At the company, we always anticipate customer needs through progress in technology development that let us respond quickly. In an environment filled with a grand total of 319 machine tool units in hand, our employees actively oriented toward development, backed up by a supportive in-house atmosphere, have been successful in the development of a large number of technologies.

At the company, we always anticipate customer needs through progress in technology development that let us respond quickly. In an environment filled with a grand total of 319 machine tool units in hand, our employees actively oriented toward development, backed up by a supportive in-house atmosphere, have been successful in the development of a large number of technologies.

With our own hands we constantly monitor the conditions for products, materials, metal molds, cutting tools, oil, shavings, and equipment, etc., and are unceasingly engaged in analysis and research, devoted daily to enable the development and provision of products that will satisfy the customer.

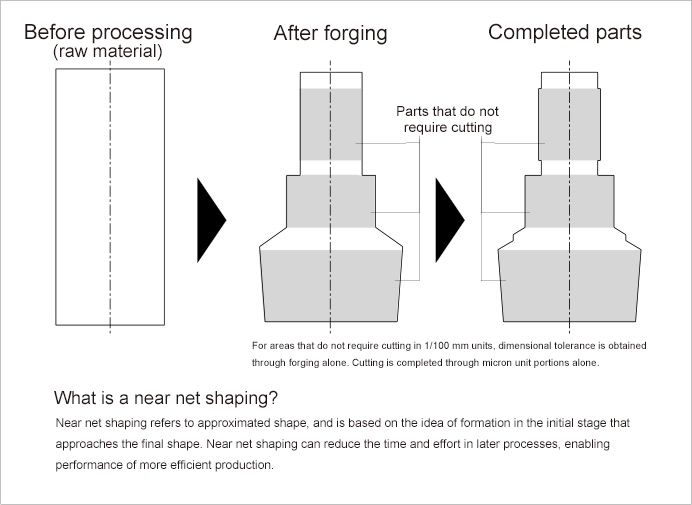

Near net shaping × Cutting technology improvement = ∞

As one technology development, we are building up a production system based on cold precision forging near net shaping. This involves use of forging alone to form a shape that is close to the final product, to cut down on the time and effort in later processes.

Another technology development is the improvements to cutting technology. In products where near net shaping has reduced the cutting allowance, cutting tool and program improvements have further boosted productivity.

ear net shaping × Cutting technology improvements can achieve unlimited research and development based on unlimited ideas.

Heteromorphic products

(cutting-less products)

Products formed by forging and press alone (Left: Forging alone, Right: Completed parts processed from casting + press). We can even perform manufacture of heteromorphic items with complex shapes other than axial items.

CAD

We use CAD for manufacture of design drawings incorporating the company know-how not found at other companies.