Quality assurance

MPP KOMATSU firmly pushes "quality first" so as to be a corporation that uses products to provide satisfaction and trust to customers.

MPP KOMATSU firmly pushes "quality first" so as to be a corporation that uses products to provide satisfaction and trust to customers.

For a single product, we perform a check that amounts to a full 20 items, covering from the materials selection stage to the completed parts, and for the final completion inspection, we use a 100% image inspection machine that assures 100% quality assurance even for products that exceed a monthly production of 1 million units.

In addition, at the company we have a certification test location based on ISO/IEC17025 acquisition. With this action, we have established a system capable of responding to world-standard quality.

20 item check

When all of the manufactured products have passed the strict inspection, they reach a finished state that satisfies customers.

Materials stage

- Outward appearance

- Hardness

- Dimensions

- Spark test

- Organization test

Wide-ranging materials and wire diameters are managed at the minimum inventory under arrangement plans, as necessary.

Cold forging process

- Outward appearance

- Fiber flow

- Dimensional precision

We have a flexible production system capable of responding to multiple parts production ranging in monthly production from over 1 million units down to 100 units

In addition, since metal molds are all in-house design, we make use of near net shaping technology and fusion of precision forging and precision cutting technology to provide the maximum cost benefits to customers.

Cutting process

- Outward appearance

- Finishing precision

- Dimensional precision

We are aware of flexibility in response to multi-item small-lot production, and maintain NC lathe, gun drill, grinder, automated straightener, and other facilities, to achieve processing from before heat processing to after heat processing.

We have prepared a system that is fully capable of responding to customer demands for delivery dates, quality, and price.

Non-oxidation heat processing

- Strength

- Organization

- Hardness

In particular, we achieve bolts with a strength of 12T.

Surface processing

- Outward appearance

- Film thickness measurement

- Chemical resistance test

- Friction coefficient measurement

We have an inline baking facility installed in the zinc plating automated line, and perform baking (hydrogen de-embrittlement) before the chromate processing, ensuring quality that is not visible in outward appearance or the film pressure number.

Completed parts inspection

- Magnetic characteristics measurement

- 100% quality

assurance

Completed parts inspection measurement room

Our completed parts inspection measurement room is equipped with measuring instruments for quality assurance, such as three-dimensional measuring instruments or friction coefficient measuring instruments. For quality improvement, we are actively introducing measuring instruments.

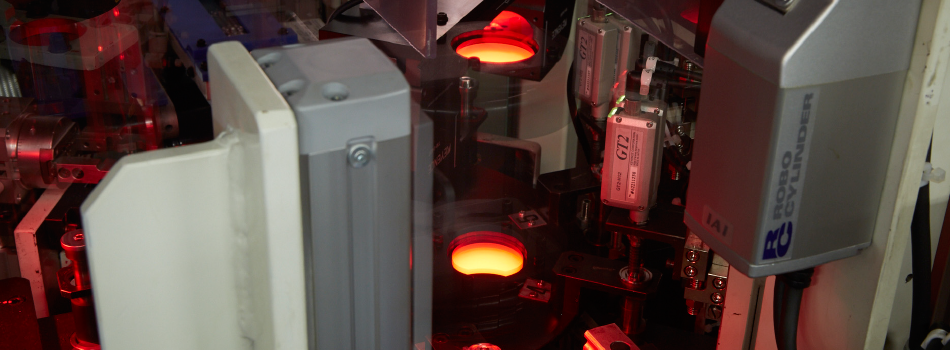

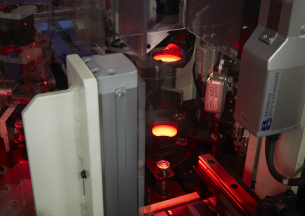

100% image inspection machine

For completed parts, we use the 100% image inspection machine to perform strict inspections of through quality, to provide 100% quality assurance.

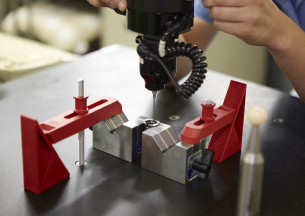

Three-dimensional measurement instrument

We can find the geometrical tolerance such as the internal and external diameter of the measurement target item, as well as the flatness, parallelism, angularity, and positioning, etc., measure the hole diameter, etc., and perform checks in 1 micron units.