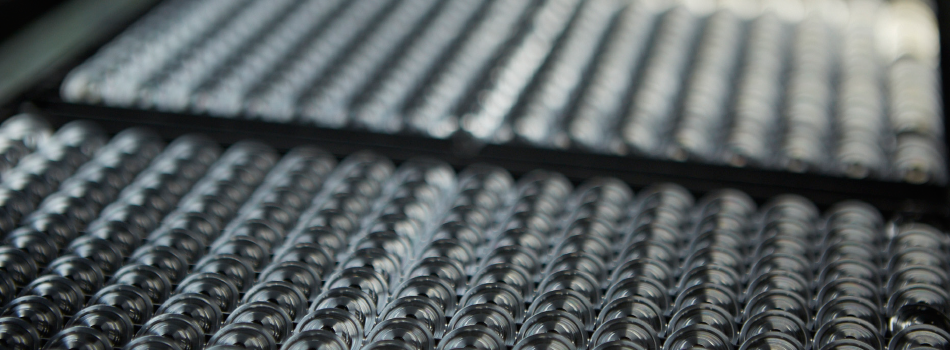

In-house integrated production system

(soft magnetic/non-magnetic parts)

At the company we combine integrated production systems from forging to plating finishing, enabling manufacture of as many as 1 million units or more a month per one part.

At the company we combine integrated production systems from forging to plating finishing, enabling manufacture of as many as 1 million units or more a month per one part.

In addition to the bold integrated process developed since the company founding, we have special heat processing (magnetic annealing, gas soft nitriding, brazing furnace) as in-house manufacture in 2015, and have established the world's only integrated process for solenoids that are the core of soft magnetic and non-magnetic parts.

Integrated production not only stabilizes quality, it can also achieve higher production speeds and lower costs, etc., and can sharply boost production efficiency.

In addition, everything up to finishing is performed in-house, so that there is no leakage of customer know-how or product information

Manufacturing flow

Cold precision forging

We have multi-stage forging machines up to a maximum of six stages, held in multiple locations. In addition to the complex shapes or heteromorphic products, processing of mass-produced parts is enabled in excess of 1 million units per month.The metal molds are all in-house design, and we are constantly engaged in improvement of die life.

Precision cutting

Among the cutting processes, we are particularly expert at lathe cutting processes, performing product formation centering on NC lathes.The cutting tools that we use during processing have been developed in-house, and we can flexibly respond to any and all shapes.

Rolling

In this processing method, we use tools called rolling dies for insertion of metal materials, and plastic deformation for shaping of screw ridges.Turning at 200 revolutions per minute, this processing achieves both manufacturing costs and mass production speed.

Grinding

For grinders that shape the product to the requisite dimensions, shape, and quality we introduce fully automated machinery.This further improves QCD.

Special heat processing (magnetic annealing, gas soft nitriding, brazing)

Magnetic annealing is used for low coercivity of soft magnetic parts, and gas soft nitriding is used to harden the surface and improve sliding. In addition, brazing is used to bond the soft magnetic parts and non-magnetic parts. 。In all processes, the processing conditions for finishing are established in low coercivity. Furthermore, performing the processing in-house enables control down to dimensional changes of a few microns caused by heat distortion or nitrogen compound layer thickness, to ensure precision dimensions in the final product for the total number.

Heat processing (thermal refining)

We perform quenching and tempering in a series of automatic processes, to manufacture high-strength products that combine hardness and tenacity. In particular, we achieve bolts with a strength of 12T.

Straightening

For the post-heat treatment processing, we have a fully automatic straightening machine that enables suppression of manufacturing costs for shafts and similar products. We can perform in-house manufacturing for all sizes of bolts, from small to large.

Plating (Zinc, chrome, Geomet® processing)

Zinc plating, nickel chrome plating, and Geomet® processing are implemented in products, for a product finish with a beautiful outward appearance and superior corrosion resistance (rust-proofing).

Inline baking

Inline baking is installed in the zinc plating automated line, enabling baking (hydrogen de-embrittlement) on all units before the chromate processing. As a result, we can offer total delay fracture assurance for high-strength bolts, and anti-corrosion assurance, etc., offering sure quality assurance that is not visible in outward appearance or the film pressure number.