Cold precision forging × Precision cutting

Cold precision forging enables one-stop processing of the product until the final shaping. In addition, for cutting, unusual complex shapes that require more time can be handled with a single mold. Precision cutting is readily performed for parts requiring micron unit precision, for efficient finishing up to the final shape.

Cold precision forging enables one-stop processing of the product until the final shaping. In addition, for cutting, unusual complex shapes that require more time can be handled with a single mold. Precision cutting is readily performed for parts requiring micron unit precision, for efficient finishing up to the final shape.

Cold precision forging and precision cutting. Combines manufacturing processes that maximize each characteristic, to enable maximum provision of cost benefits to the customer.

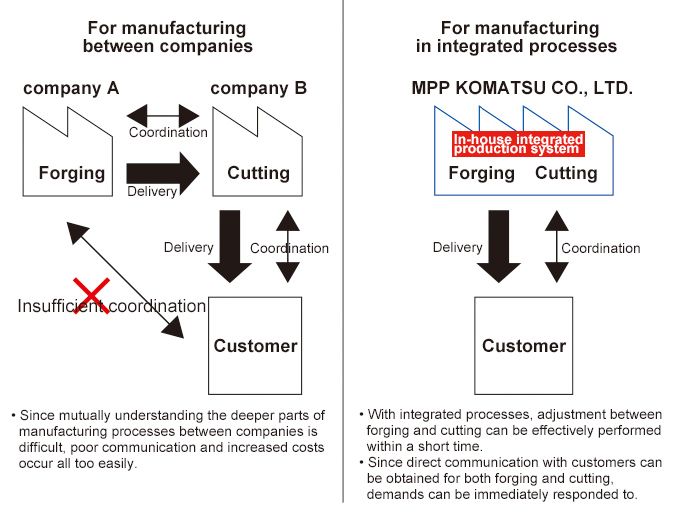

Merits of integrated processing

If forging and cutting are respectively performed at separate companies, in the exchanges between the companies, coordination becomes difficult, the work speed slackens and minimization of costs becomes difficult.

Since at our company we can combine both the forging and cutting manufacturing processes, it is easy for us to take into consideration the mutual characteristics of the products, for micro-adjustments to achieve the best balance, as well as to achieve a speeding up of the manufacturing time and minimization of costs.

Metal molds we own

At the company, we own as many as several hundred different metal molds. We can respond to a wide range of customer needs that change with the times.

Forge molding

A comparison of products achieved by forging only and by forging and cutting together. (Left: Forging only, Right: Forging and cutting process completed) With forging, we can mold shapes for virtually complete parts。